Our Jaw Crushers Feature:

Oversized Shaft, Dynamically Balanced Flywheels

All Lippmann heavy-duty jaw crushers feature an oversized, heat treated shaft forged of special alloy to provide an exceptionally large eccentric throw. These heavy-duty shafts are paired with two dynamically balanced flywheels, effectively reducing vibration on both portable and stationary crushers. The overhead eccentric configuration does not rely on gravity alone to move material through the chamber. Rather, the inward and downward movement of the swing jaw provides for a forced-feeding motion to maximize output. All shafts are machined and put through a rigorous inspection process before they enter production.

Tapered Roller Bearing for Optimized Bearing Life

In order to optimize bearing life, only tapered roller bearings are used in Lippmann jaw crushers. The tapered bearings offer a combination of features that spherical bearings are unable to provide. When considering the adjustable clearance, line contact, true rolling motion and ability to carry both radial and thrust loads, the tapered roller bearing is an obvious choice for all jaw crushers. Lippmann proudly stocks a large inventory of all bearing sizes.

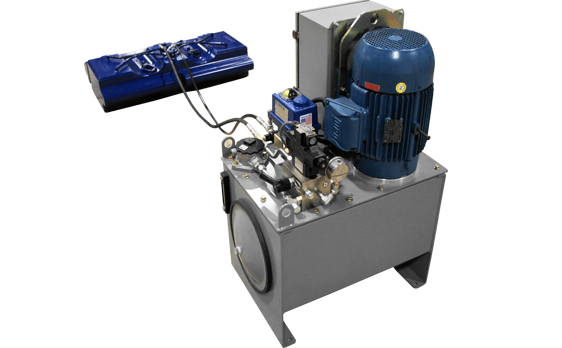

Hydraulic Toggle Reduces Setting Time

The automatic hydraulic toggle has greatly reduced the time it takes to change a jaw crusher’s setting. As jaw dies wear, the hydraulic toggle can be easily adjusted to maintain a constant closed side setting while in continuous operation. An added benefit of the Lippmann hydraulic toggle package is the ability to provide tramp release once an un-crushable has entered the crushing chamber. Nitrogen-powered automatic hydraulic toggles are available on all mid-sized to large model jaw crushers.

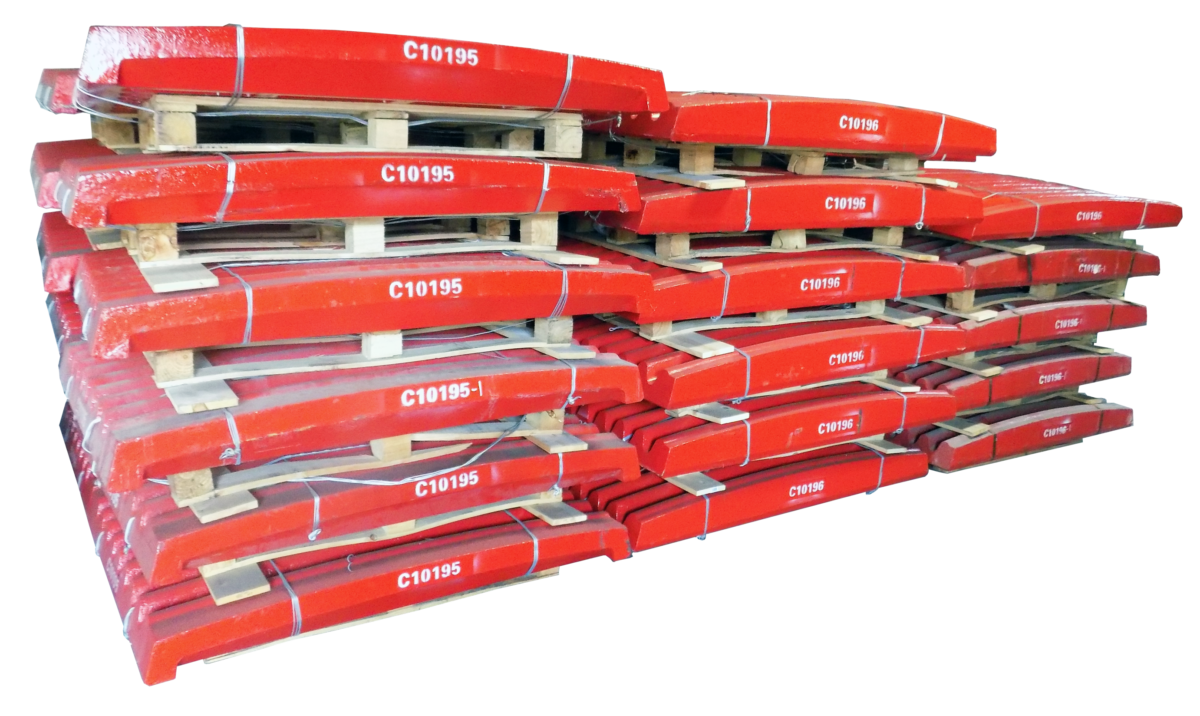

Reversible Jaw Dies for Longer Life

The automatic hydraulic toggle has greatly reduced the time it takes to change a jaw crusher’s setting. As jaw dies wear, the hydraulic toggle can be easily adjusted to maintain a constant closed side setting while in continuous operation. An added benefit of the Lippmann hydraulic toggle package is the ability to provide tramp release once an un-crushable has entered the crushing chamber. Nitrogen-powered automatic hydraulic toggles are available on all mid-sized to large model jaw crushers.

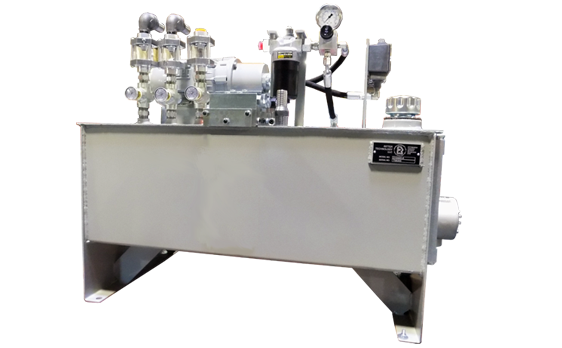

Oil-Bath Lubrication System

The automatic hydraulic toggle has greatly reduced the time it takes to change a jaw crusher’s setting. As jaw dies wear, the hydraulic toggle can be easily adjusted to maintain a constant closed side setting while in continuous operation. An added benefit of the Lippmann hydraulic toggle package is the ability to provide tramp release once an un-crushable has entered the crushing chamber. Nitrogen-powered automatic hydraulic toggles are available on all mid-sized to large model jaw crushers.