“Lippmann builds stuff heavy, and heavy duty. I really put a lot of value in something that’s built for the long haul.” comments Dean Soiland, President of BoDean Company.

“You keep feeding it material, and she keeps crushing. This allows us to keep on making rock and getting it out there to the customer,” comments Charles Shackelford, Quarry Manager for Charles DeWeese Construction

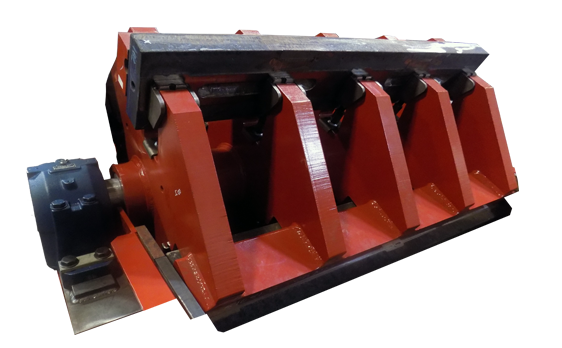

Lippmann impact crushers are fabricated to provide cost efficient crushing solutions to customers, without losing strength or efficiency.

Our Impact Crushers Feature:

Long Life Hammers

Hammers are rectangular in shape with four wear positions. This shape provides the most even production and product gradation. When utilized correctly, each blow bar will offer four flips, extending the life of the wear components. Depending on the application, Lippmann can provide a variety of different hammer compositions. From high chrome, high carbon limestone applications to low chrome, low carbon recycle applications, Lippmann is able to provide the correct blow bar for the job.

Premium Shaft and Rotor

The premium, high alloy steel shaft is held with keyless locking assemblies. These keyless locking rings offer superior locking capabilities over keyed shaft applications due to the impact bending loads that are experienced. The rotor houses premium blow bars using a jack and stand configuration. The force of the jacking assembly causes the hammers and rotor backing beams to act as a solid mass while crushing. This rigid, machine fit enables the use of more wear resistant, higher chrome hammers and yields greater production before turning or replacing hammers.

Easily Adjustable Curtains and Wear Resistant Liners

To ensure efficiency, all frame and apron liners are drilled and tapped using a standard hex head cap screws and locking washers. Liners are a premium, abrasion-resistant materials that are easily replaceable after wear. Curtain position is maintained through a combination of both gravity and spring loaded configurations, allowing for easy adjustment from outside of the crusher.

In any crushing scenario, attention to detail is of utmost importance to maximize crushing efficiency and profitability. Lippmann sales representatives are dedicated to analyzing a customer’s crushing application and choosing the most cost efficient equipment to get the job done. This concept has been fortified with customizable portable plants, offering numerous options for plant design and ensuring customer satisfaction.