Lippmann Rip Rap plants are completely self contained, portable units designed for optimal screening and scalping of material.

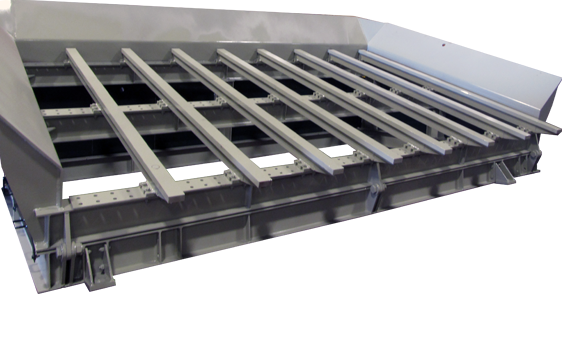

The Lippmann Model 6224 Rip Rap Plant is equipped with a massive 62” x 24’ feeder sized specifically to offer more capacity than its competitors. The feeder consists of two 5’ grizzly sections with adjustable bars. The material passing through the first deck of grizzly bars is side discharged via conveyor, while larger material passing through the second deck is discharged through a box-like discharge chute. All remaining oversized material is discharged over the heavily lined front discharge chute.

Our Rip Rap Plants Feature:

Finger & Grizzly Installation

Depending on the application, grizzly bars, grizzly fingers, or a combination of both can be included on the 6224 RipRap. Contact your local sales representative for additional information.

Rear Diesel Genset

On-board diesel gensets allow the operation of the Lippmann RipRap plants in even the most remote locations. Electric panels contain two additional starters allowing for two off plants conveyors.

Easy Access to Chutes at Better Angles

Shallow chutes and short conveyors are a thing of the past. The re-vamped RipRap plant features a folding side discharge conveyor under the first grizzly section and massive discharge chute under the second section.

Hydraulic Tipping Grizzly

Tipping grizzlies can be added to Lippmann RipRap plants to control top size of material. These units are sloped to allow some material to roll off, away from the plant.

The Lippmann Rip Rap plant offers an array of options allowing customers the ability to customize their plant. A popular add-on is a variable frequency drive that permits operators to regulate the flow of material through the plant. Another option is swapping grizzly bars out for finger cartridges. Depending on the application, it may be advantageous to change out grizzly bars for fingers or use a combination of both. A unique feature about this model is allowing operators to choose between electric or diesel driven plants, without losing any portability.

The 6224 Rip Rap Plant is designed to allow for the installation of a diesel genset on the rear of the unit. An excellent option if off plant conveyors are in operation.