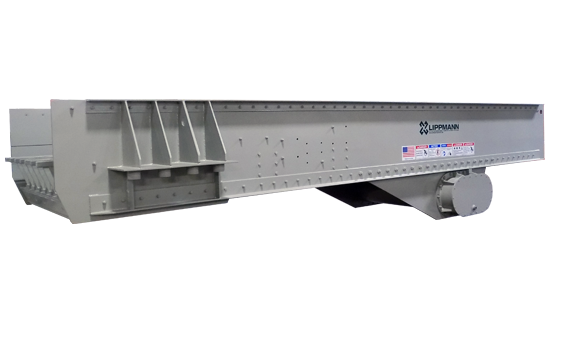

Lippmann heavy-duty vibrating grizzly feeders are ruggedly constructed for proven, dependable, and continuous operation. These built-to-last feeders do a superior job of metering the material to the crusher, removing fines from the crushing circuit, and absorbing impact from material of various densities and sizes.

Lippmann-Milwaukee, Inc.

3271 East Van Norman Ave.

Cudahy, WI 53110-0586

USA

(800) 648-0486

Our Feeders & Screens Feature:

Strong, Trouble-Free Operation

The two overriding advantages of the Lippmann series feeders are the sound design and maximization of strength. To ensure strong, trouble-free operation, Lippmann engineers have designed the vibrating gold rush grizzly feeder for maximum strength at all crucial stress points. Each aggregate feeder features extra heavily reinforced cross members that run the entire course of the unit. Adding to the strength and overall durability, each Lippmann vibrating feeder comes standard with replaceable steel liners on the feeder pan and side plates.

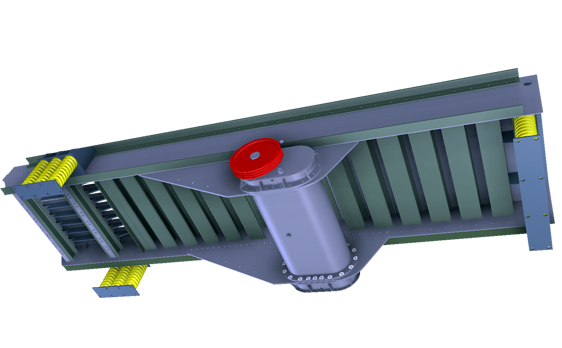

Field-Proven Eccentric Drive Mechanism

Due largely to extensive stress analysis and finite element techniques employed by Lippmann engineers, Lippmann has successfully created a heavy-duty feeder that will suit any crushing application. Gold rush gold feeders are driven by a dual shaft, field-proven eccentric drive mechanism. The flow-through tube arrangement of the vibe housing encases a large oil reservoir that both continuously lubricates all moving components and disperses heat. All vibe units are protected by a double seal arrangement; guarding against any foreign contaminant that would otherwise enter the mechanism.

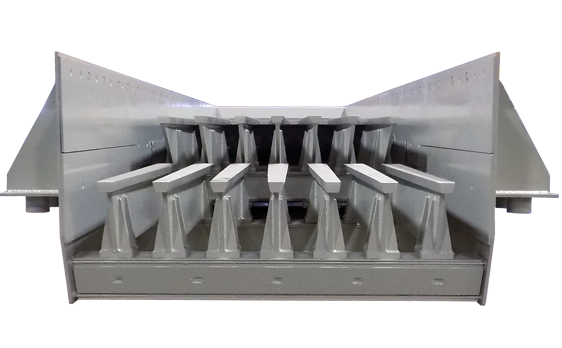

Choice of Adjustable Grizzly Configurations

When looking to remove large amounts of material from your crushing circuit, Lippmann offers a wide array of grizzly configurations which are built to suit the customer’s every need. Available on all Lipmann feeders are tapered, steel grizzly bars. These bars have a self-cleaning design and are fabricated to be both replaceable and adjustable.

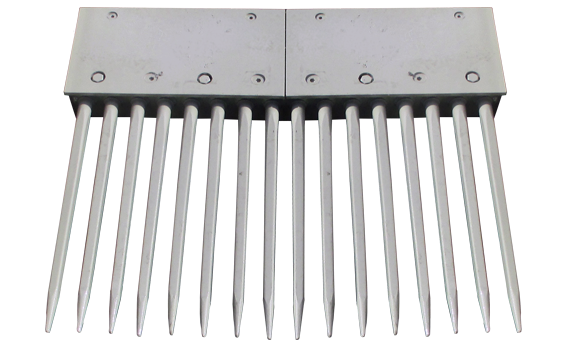

Lippmann Grizzly Finger Cartridges

An additional option on all feeders is replacing grizzly bars with Lippmann grizzly spring fingers. These steel fingers are loaded into the wash feeder as a single, cartridge-like unit. Lippmann fingers have a distinct advantage in some applications due to their ability to “cut” material and remove large quantities of undersized material before entering the crusher.

Low Profile Design

Low profile side plates minimize height which is critical for road-able crushing plants. Heavy coil springs at each side on the discharge end isolate vibrations and stabilize the gold rush feeder for smooth operation.